Products

Furukawa Electric TEX-E is a high-performance Class E triple-insulated winding wire with reinforced insulation, compliant with IEC and UL standards. Ideal for compact, high-voltage transformers and solderable for easy integration. TEX-E triple insulated wire offers superior thermal endurance (120–130°C), 1000Vrms working voltage, and compact design. Certified by global safety standards including UL, VDE, and IEC. Get compact, safe, and efficient performance with TEX-E triple-insulated winding wire—IEC61558-1 certified, solderable, and perfect for high-frequency, high-voltage applications. Commonly used in switch-mode power supplies, LED drivers, medical power modules, automotive electronics, and compact consumer and industrial equipment where reinforced insulation and space efficiency are essentia

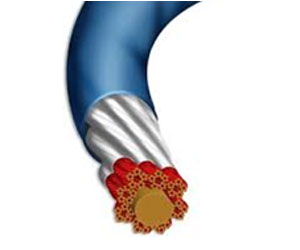

LITZ Wire

Triple-insulated 7 strand TEX-ELZ Litz wire by Furukawa Electric ensures high frequency performance, solderability, and compliance with IEC61558-1 and UL standards. Designed for safe, compact, and energy-efficient designs. TEX-ELZ Litz wire combines high thermal resistance (Class E, 120°C) with superior flexibility and electric strength. Perfect for efficient, compact, and high-frequency applications. Ideal for downsized transformers and rated up to 1000 Vrms. Widely used in high-frequency transformers, inductors, wireless charging coils, RF applications, and power electronics to minimize skin effect and proximity losses, ensuring higher efficiency and reduced heat generation in AC and high-frequency circuits.

Self-Solderable Wire

Self-solderable wires ensure clean solder joints, high dielectric strength, and reliable performance at elevated temperatures. It enables direct soldering in compact electronic assemblies. Enhance productivity with self-solderable wire engineered for high thermal endurance and easy soldering, perfect for coils, and high-frequency devices. Used in coil windings for relays, solenoids, small motors, and other electronic components where direct soldering without prior insulation removal enhances manufacturing efficiency and reliability.

Self-Bonding Wire

Self-bonding wire ensures excellent cohesion, dielectric strength, and dimensional stability under extreme thermal stress. Combines high thermal class electrical coating with a bondable topcoat, delivering strong interlayer adhesion, mechanical durability, and enhanced coil integrity. Offers high coil stability and uniform winding tension. Commonly used in voice coils, compact motors, and precision wound components, its heat-activated adhesive coating enables coil stability and shape retention without the need for additional impregnation varnish.

High Temperature Wire

High temperature wire with advanced materials that resist thermal degradation, ensuring stability and performance in extreme heat conditions. Offers excellent dielectric strength and flexibility. With superior thermal endurance, It delivers consistent conductivity, low dielectric loss, and robust insulation even in high-stress thermal environments. Designed for use in aerospace, automotive engines, industrial ovens, and electrical equipment operating under extreme thermal conditions, maintaining integrity and reliable performance at elevated temperatures.

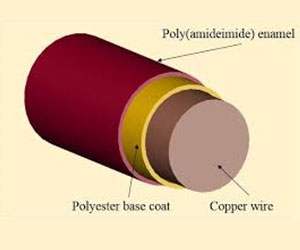

Dual Coated Wire

Dual-coated wire features a robust polyester base with a polyamide-imide enamel top layer, ensuring high thermal stability, excellent dielectric strength, and superior mechanical strength. Provides enhanced resistance to abrasion, solvents, and overloading, making it suitable for high-performance electrical and magnetic applications. Designed to withstand demanding thermal classes, it offers reliable performance in motors, and other equipment operating under continuous high-temperature and mechanical stress. Extensively used in electric motors, and generators, high thermal stability, and mechanical strength are essential for long-term reliable operation.

Nylon & Teflon Coated Wires

Nylon & Teflon-coated wires ensure superior resistance to chemicals, high temperature and electrical breakdown. The dual-layer insulation combines a durable nylon outer jacket for excellent abrasion and moisture resistance with a Teflon (PTFE) inner layer that maintains exceptional dielectric strength and flexibility under extreme thermal and mechanical stress—engineered to meet rigorous industry standards, delivering reliable performance, extended service life, and consistent electrical integrity even in harsh operating conditions. Utilized in aerospace, automotive, and industrial electrical systems where exceptional resistance to chemicals, abrasion, and electrical breakdown is critical for durability and safety.